Petrochemical Ventilation Filtration Solutions

The petrochemical industry operates in environments with high-temperature, highly corrosive, and highly polluting gases. Ventilation systems must meet very exacting requirements for cleanliness and stability. The installation of a high-efficiency gaseous molecular contaminant control system for central control rooms, electronic control equipment and operator health is therefore critical ensure the stability and sustainability of the production process.

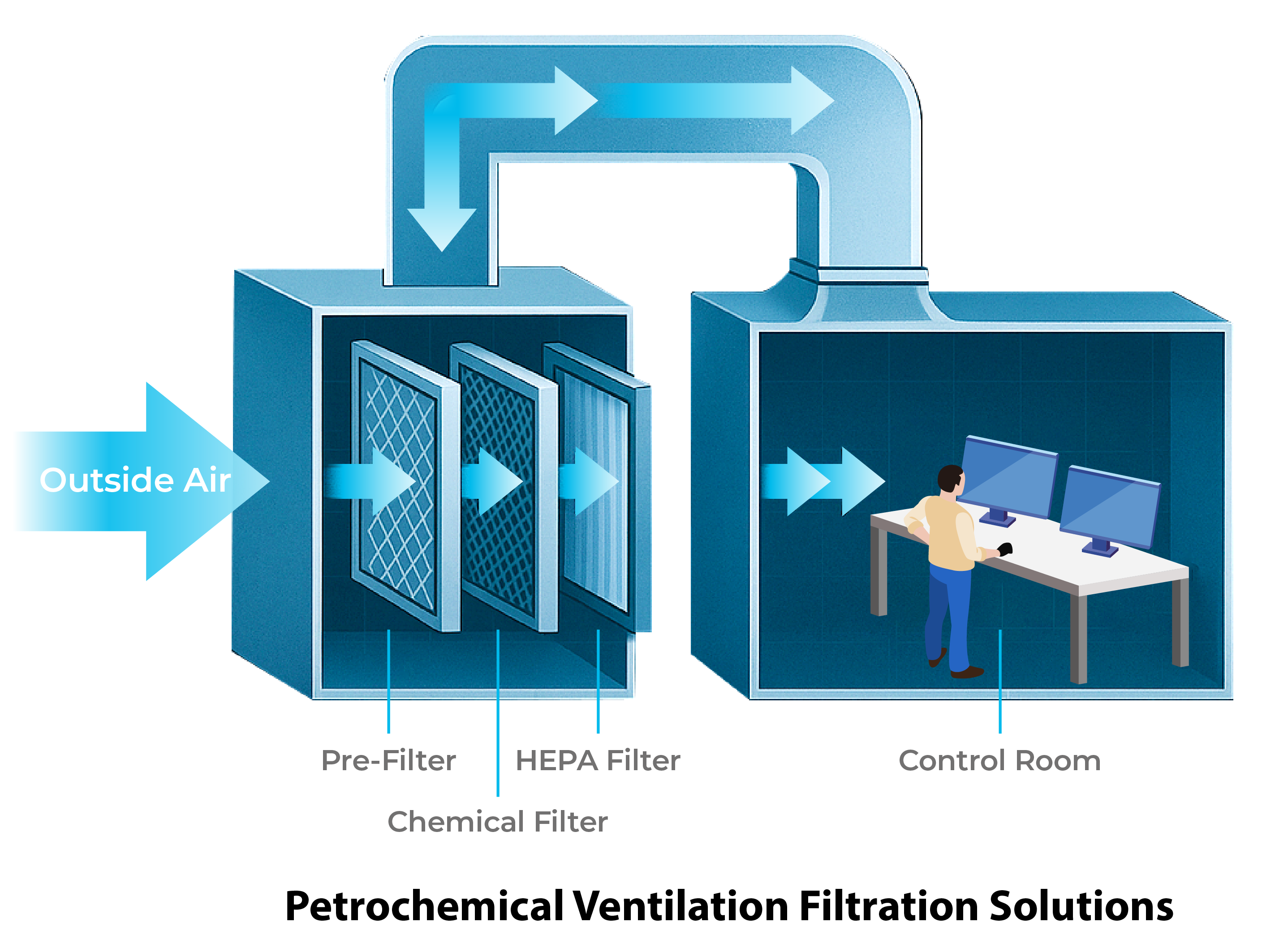

Outside air is filtered through a three-stage filter (primary filter, chemical filter, high-efficiency filter) to become stable, clean air ducted into the operating space, effectively blocking out corrosive gases and fine suspended particles.

The chemical filter and ventilation filtration solution designed by Yesiang for petrochemical environments can effectively remove gaseous molecular contaminants, reduce the risk of corrosion, and help businesses comply with environmental safety regulations as well as sustainability standards.

Key Features

- Multi-stage protective structure → Three-stage filter combination for multi-layered filtration and total protection

- Regenerative filter media → Regenerative filter technology is used to reduce consumable costs and carbon emissions

- Custom chemical filter design → Custom configurations based on type of gases (acidic, alkali, organic)

- Support for explosion-proof and corrosion-proof design → Suitable Zone 1/Zone 2 hazardous areas

- Custom filter module and pressure loss optimization recommendations

Application Scenario

- Ventilation system for raw material storage tanks

- Air treatment equipment for explosion protection zones

- Gas filtration system for control rooms/instrument control center

- Positive pressurization system for conduit passages and indoor air conditioning

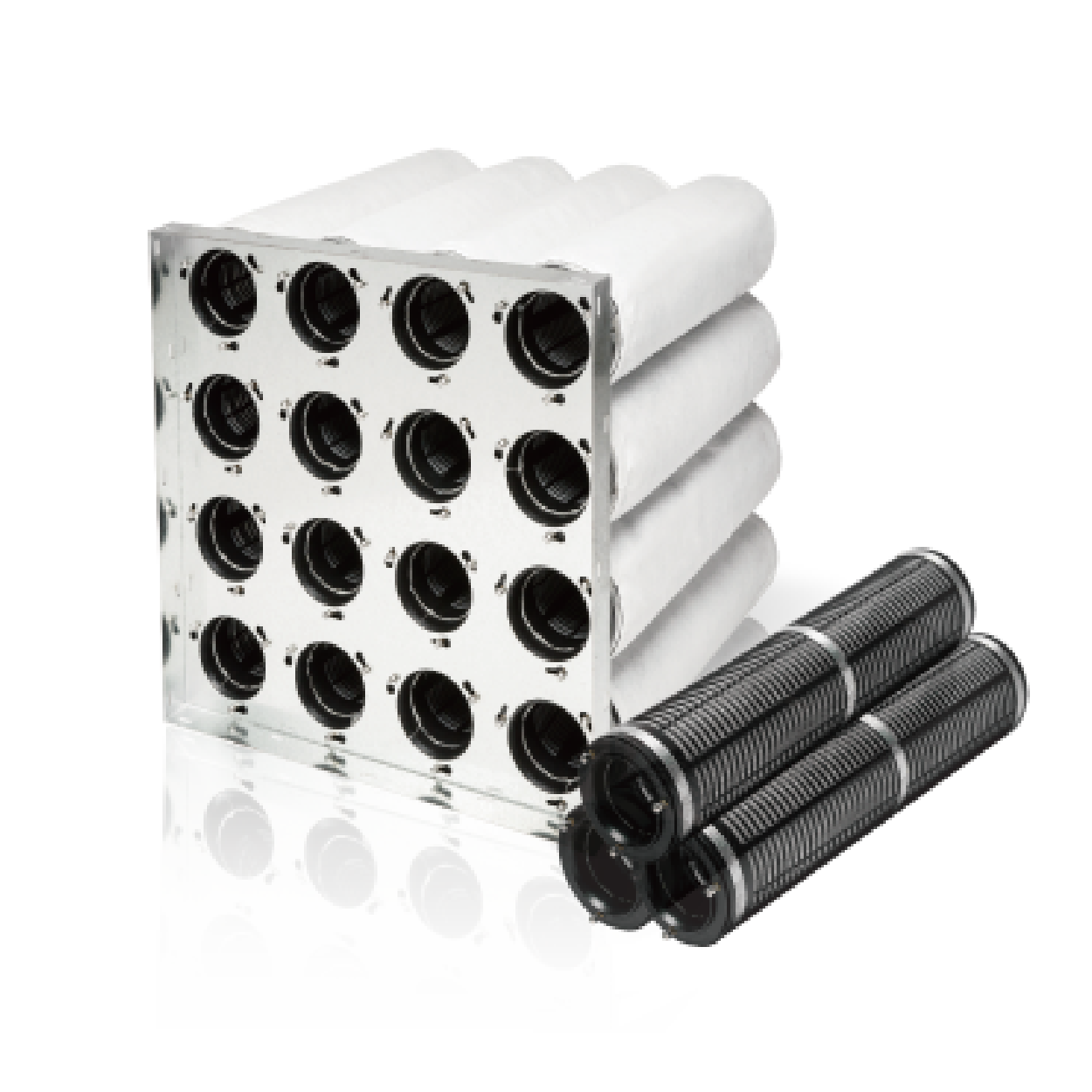

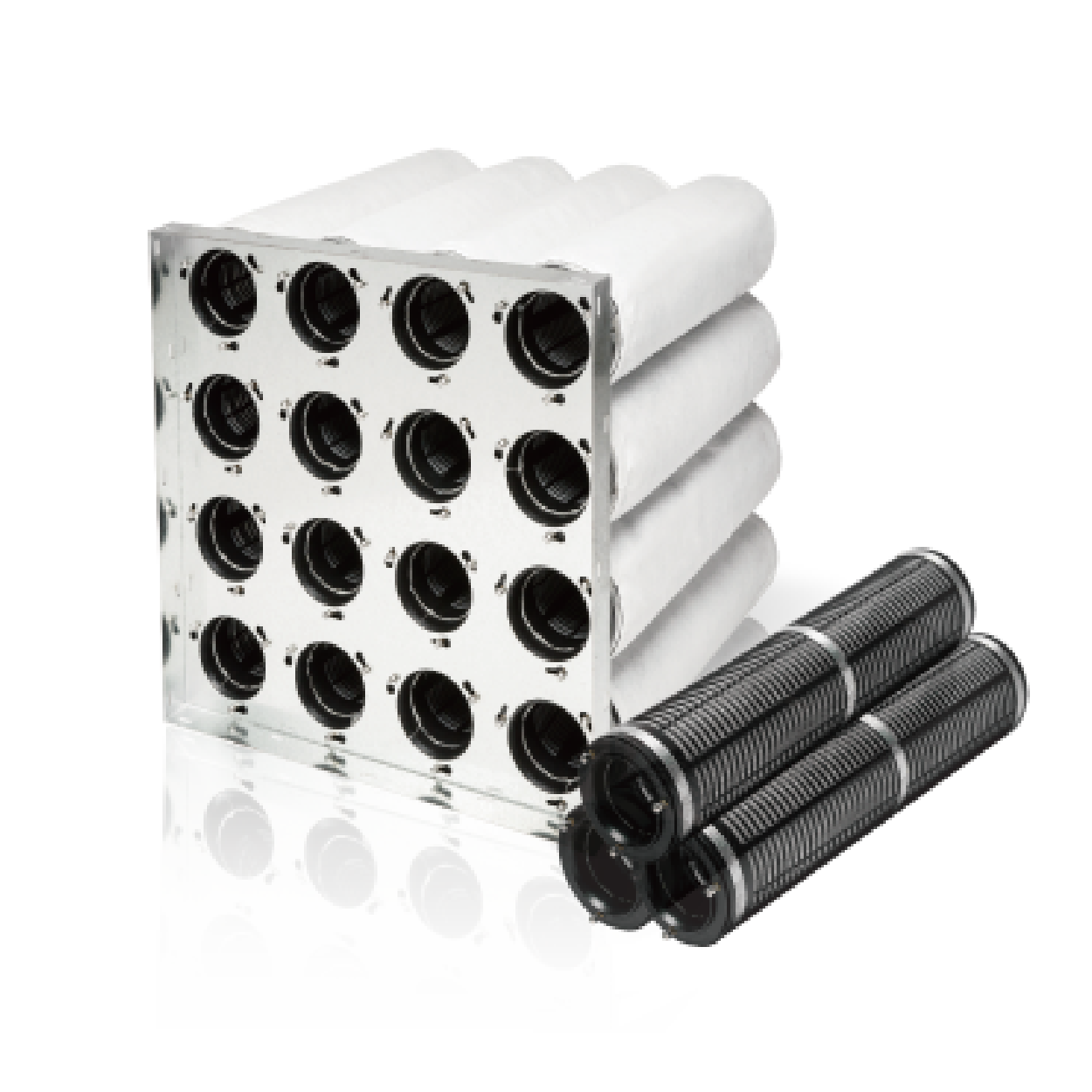

Chemical Cylinder Filter

Related Products

Chemical Cylinder Filter

- Used for high-flow inlet for high efficiency, low pressure loss and long service life

- Circular economy-compliant with 99% re-usability and high regeneration performance

- Quick detach design for improved serviceability

- ISO 14067 certification and reduces carbon emissions by 36% compared to disposable products

Installation location

MAU / FFU / RCU / Dry coil / Tools

Removes gases

VOCS, Base, Acid, H2S, DMS, CS2, NH3, O3

Frame material

Stainless steel frame / Aluminum frame / ABS frame / PP frame