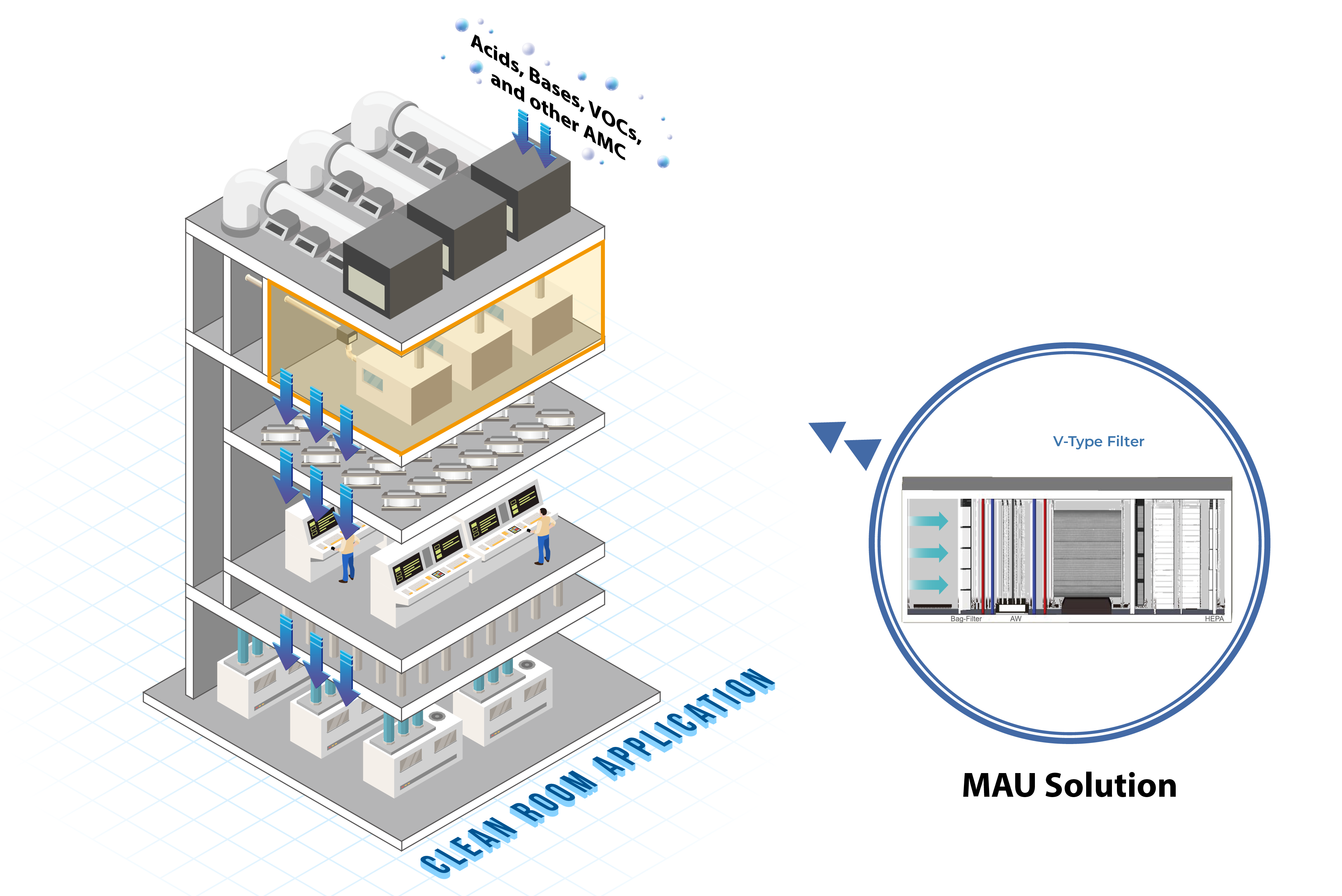

MAU(Make-up Air Unit) Solutions

Make-Up Air Unit (MAU) is the core component in the preliminary processing of make-up air within the clean room circulation system. MAU determines the quality of indoor air, and in turn, the plant’s environmental conditions, production efficiency, and product quality. It is therefore considered the first line of defense in ensuring the continuity of clean room operations.

Key Functions

- Suspended particles filtration

- Gaseous molecular contaminant filtration

- Maintaining positive indoor pressure

- Control of temperature and relative humidity

Operating Principle

When the absolute humidity of outside air is higher than the target humidity of the clean room, pre-cooling coils in the system are used to reduce the dew point of the outside air. Pre-heating coils then heat the air flow to a suitable temperature to ensure that air being channeled to the clean room is maintained at the strict temperature and humidity requirements set by the clean room once it is mixed with the sensible heat air flow from the equipment. Finally, high-efficiency filters are fitted at the outlets to filter out over 99.7% of particles and effectively remove all types of AMC in order to meet the ultra-high cleanliness standard of the clean room.

MAU must process large volumes of outside air so it accounts for the bulk of the energy consumption within the clean room circulation system. Improvement of its energy efficiency is therefore of utmost importance.

YESIANG MAU Solution

Yesiang offers professional solutions that balance high filtration performance with energy efficiency and carbon reduction based on the nature of MAU operations. Key features include:

- Wide selection of filters: Conventional V-type single-header and box-type chemical filters are available for all type of MAU design specifications on demand.

- Patented cylindrical filtration system: The proprietary cylindrical filtration system developed by Yesiang offers higher filtration efficiency with lower pressure loss to effectively reduce energy consumption and improve contaminant removal performance.

- Internationally certified energy-saving filter media: Yesiang chemical cylinder filters have passed ISO 14067:2018 carbon footprint verification and BS 8001:2017 circular economy certification. Carbon emissions are 25% lower compared to disposable filter media to help customers realize their energy-efficiency and carbon reduction targets.

Customers that use the Yesiang MAU solution can achieve optimal AMC control, improve clean room stability, and meet their sustainable development goals (ESG). This translates into a solid business advantage for the very competitive semiconductor and high-tech industries.

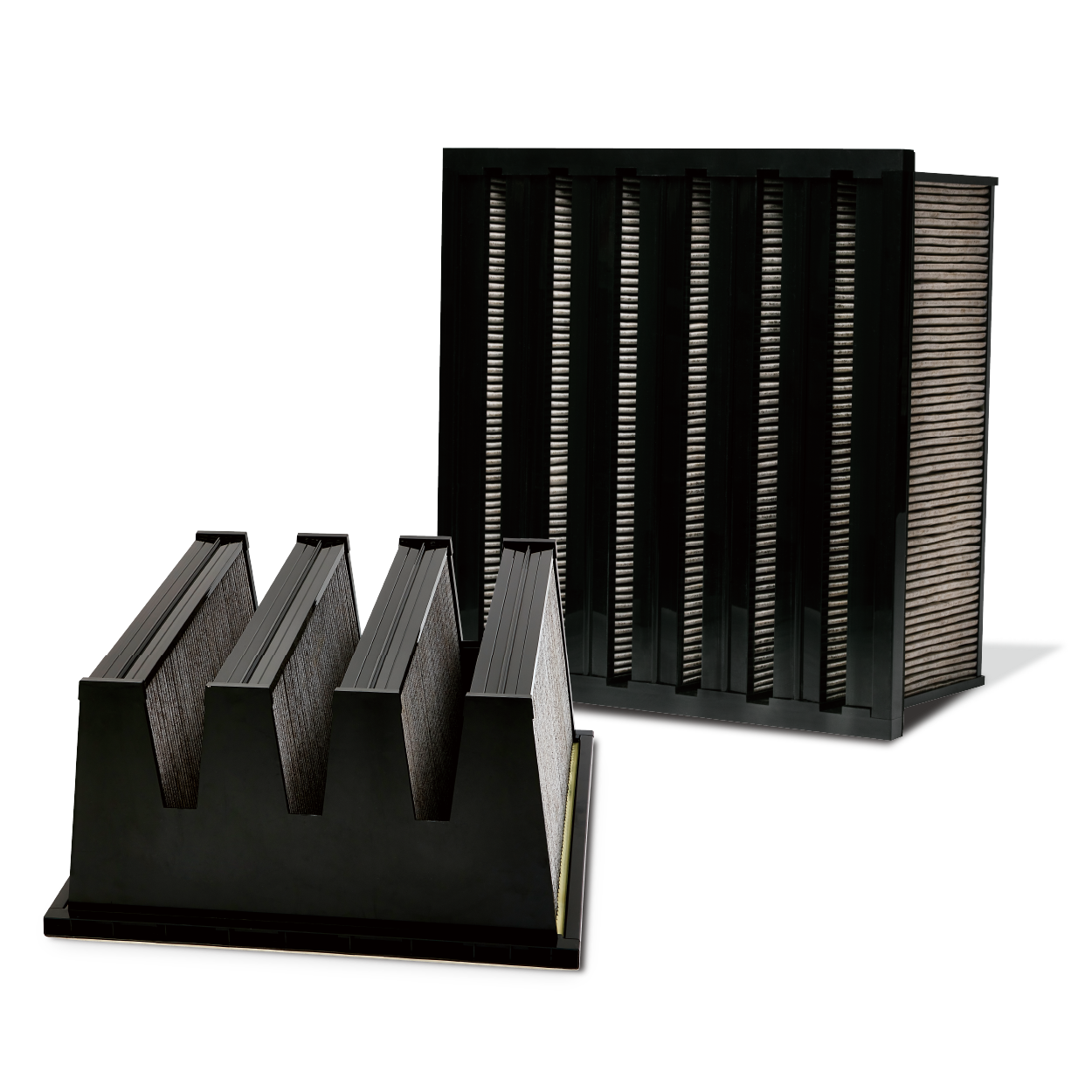

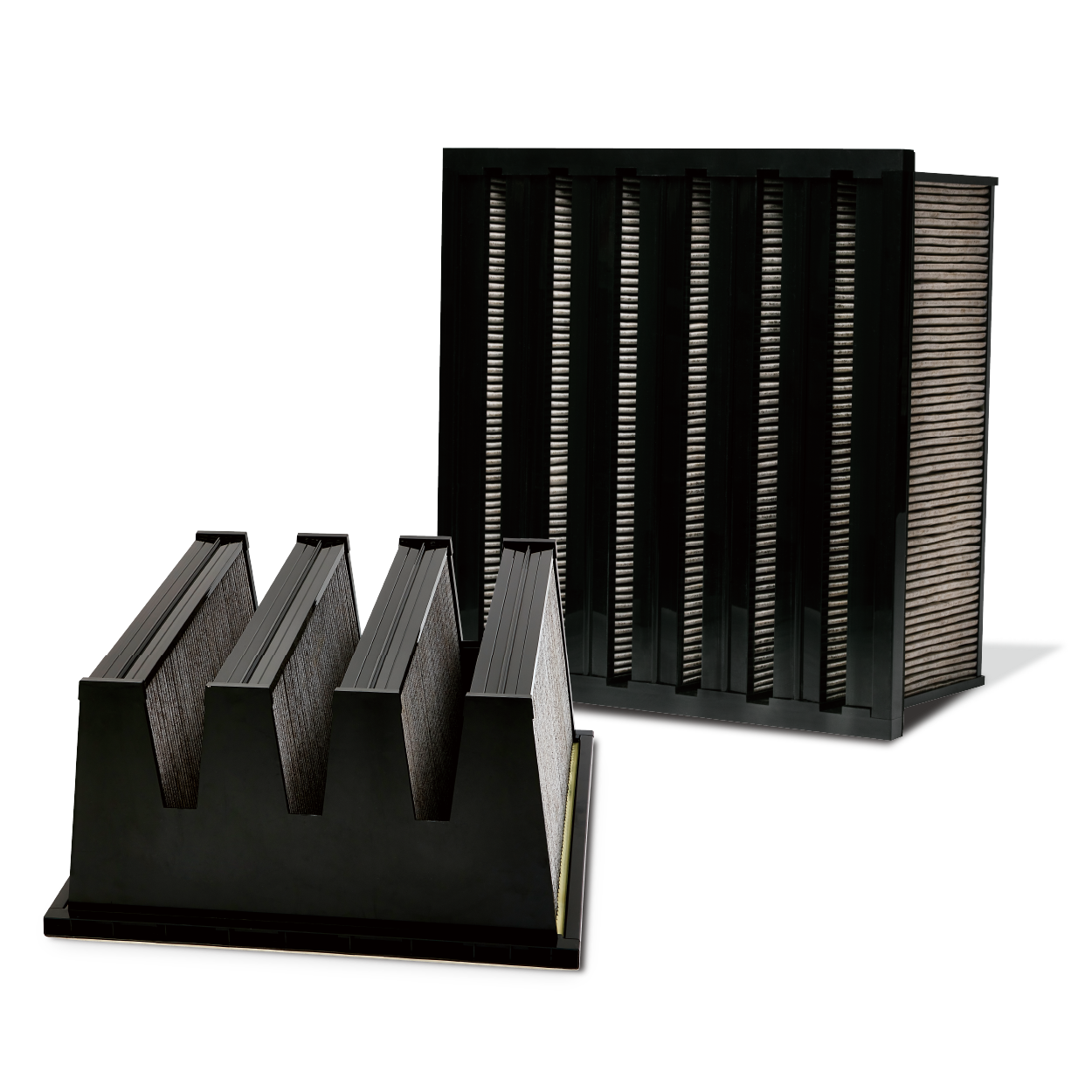

4V/ 6V Single Header Chemical Filter

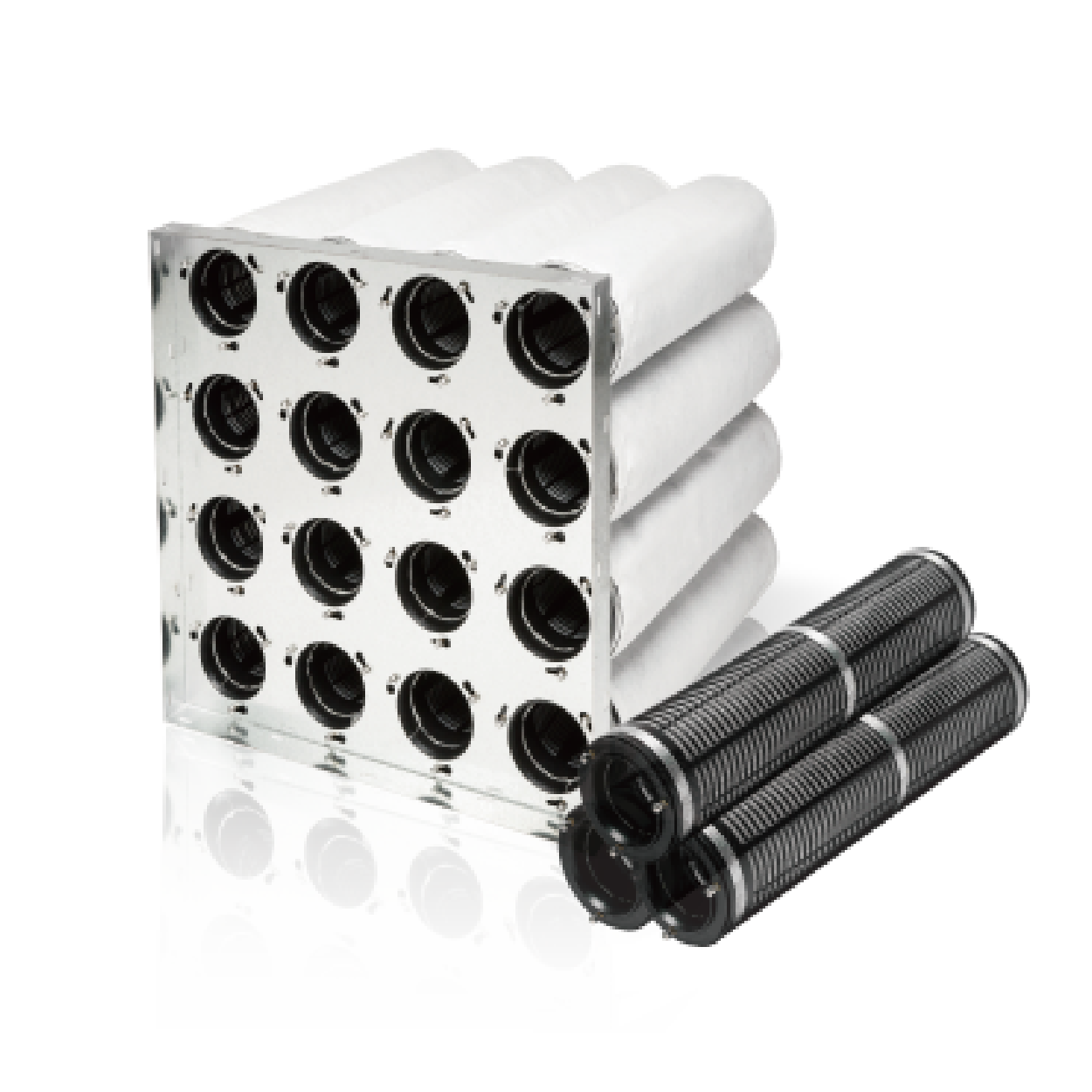

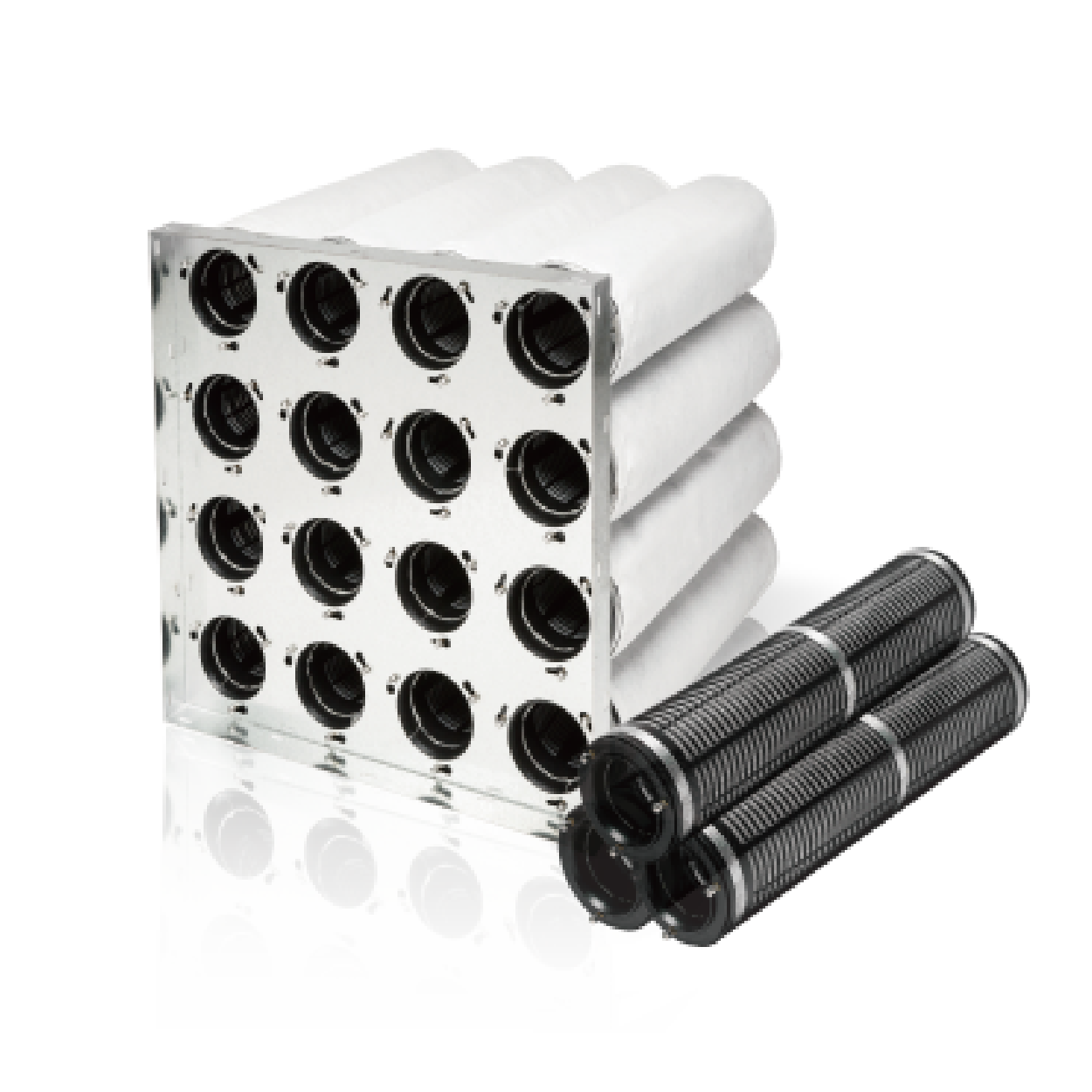

Chemical Cylinder Filter

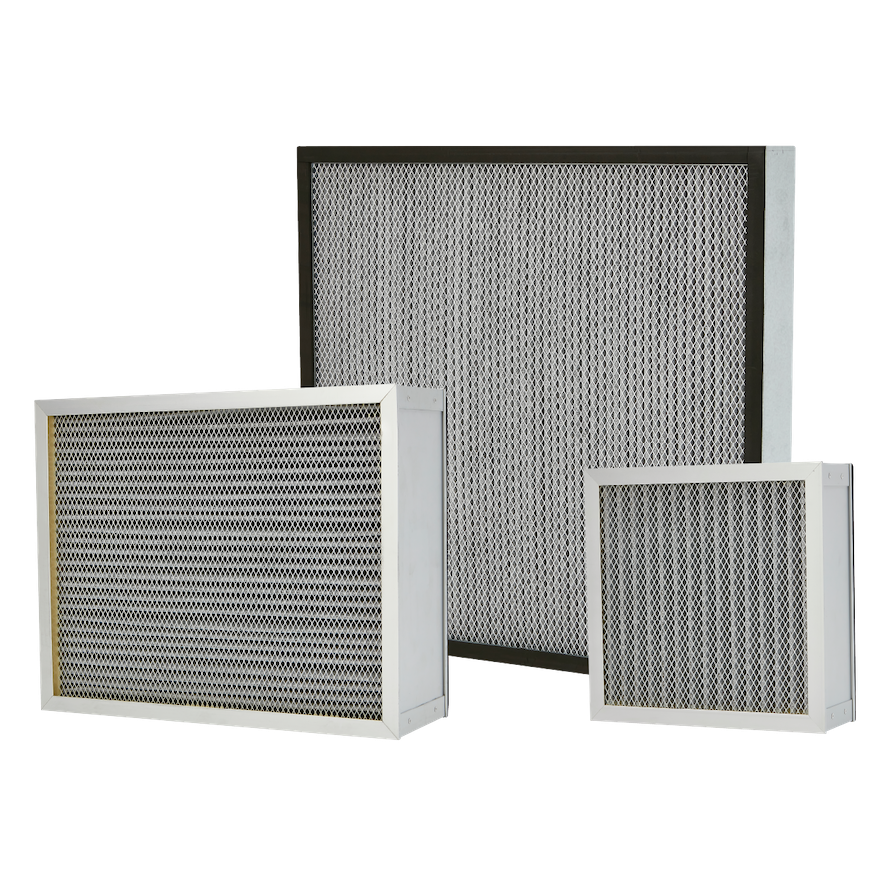

6V Box-Type Chemical Filter

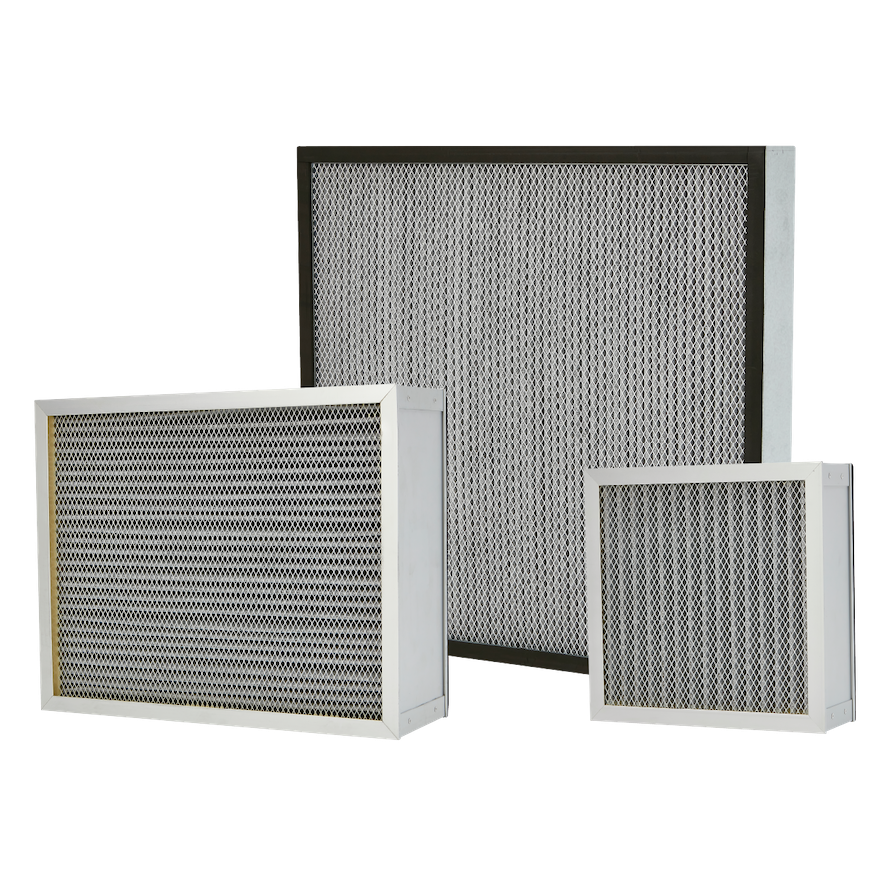

Panel Type Chemical Filter

Related Products

4V/ 6V Single Header Chemical Filter

- Suitable for high-flow operating environments to ensure optimal air circulation performance

- Enlarged filter surface area for high filtration and energy efficiency

- Support for rapid mounting and installation using existing brackets for more convenient construction

- 100% compatibility with many types of existing systems with support for future scaling and integration

Installation location

MAU / FFU / RCU / Dry coil / Tools

Removes gases

VOCs, Base, Acid, H2S, DMS, CS2, NH3, O3

Frame material

Stainless steel frame / Galvanized frame / Aluminum frame / ABS frame / PP frame

Chemical Cylinder Filter

- Used for high-flow inlet for high efficiency, low pressure loss and long service life

- Circular economy-compliant with 99% re-usability and high regeneration performance

- Quick detach design for improved serviceability

- ISO 14067 certification and reduces carbon emissions by 36% compared to disposable products

Installation location

MAU / FFU / RCU / Dry coil / Tools

Removes gases

VOCS, Base, Acid, H2S, DMS, CS2, NH3, O3

Frame material

Stainless steel frame / Aluminum frame / ABS frame / PP frame

6V Box-Type Chemical Filter

- Suitable for high-flow operating environments to ensure optimal air circulation performance

- Enlarged filter surface area for high filtration and energy efficiency

- Support for rapid mounting and installation using existing brackets for more convenient construction

- 100% compatibility with many types of existing systems with support for future scaling and integration

Installation location

MAU / FFU / RCU / Dry coil / Tools

Removes gases

VOCS, Base, Acid, H2S, DMS, CS2, NH3, O3

Frame material

Stainless steel frame / Galvanized frame / Aluminum frame / ABS frame

Panel Type Chemical Filter

- Flexible dimensions that can be used in different kinds of applications

- Available in wide range of dimensions and specifications to meet production requirements on demand

- High-efficiency filtration and long service life

- Extensively used in FFU and all types of tools

Installation location

FFU / Tools

Removes gases

TS, DMS, Acid, Base, TVOC, CXF, IPA, Acetone

Frame material

Stainless steel frame / Galvanized frame / Aluminum frame / ABS frame